.jpg)

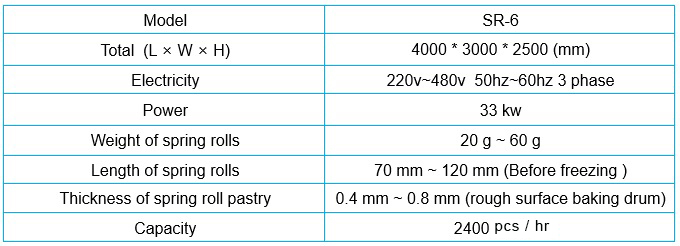

● Model : SR-6

● Length of spring roll : 70 mm - 120 mm (Before frozen)

● Weight of spring roll : 20 gram - 60 gram

● Size of spring roll pastry : 127 mm - 190 mm

● Capacity : 2400 pcs/ hr

● The machine can be customized based on your requirement.

Specifications

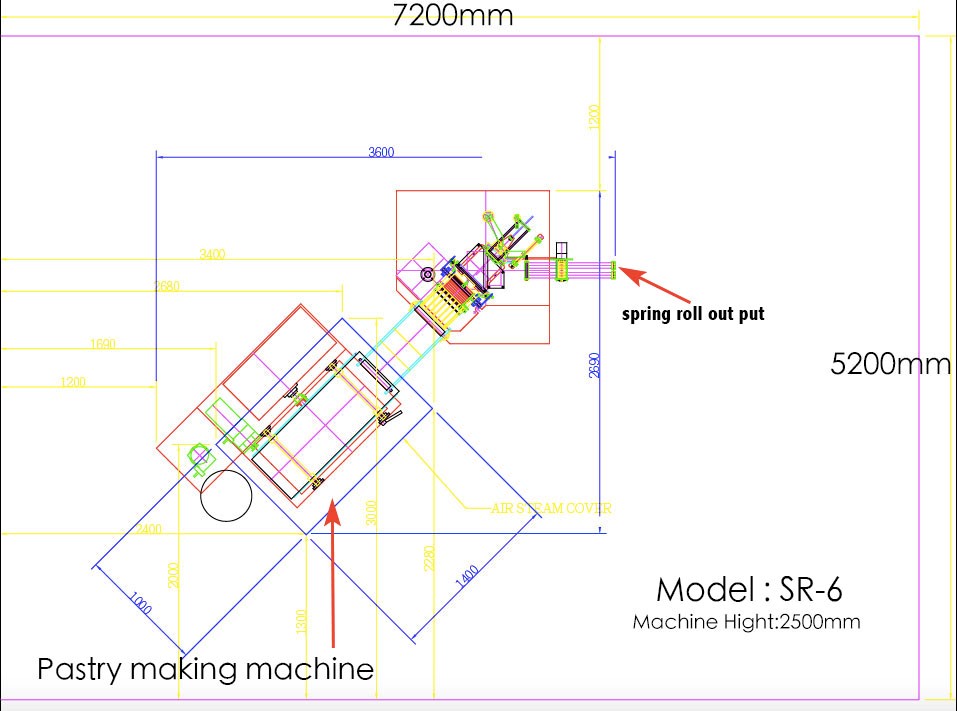

● Automatic spring roll making machine including :

A. Pastry baking machine: For

produce spring roll pastry.

B. Spring roll wrapping machine: For put the filling on the

pastry and wrap spring rolls.

Used Space :

Introduction to Spring Roll Production Line

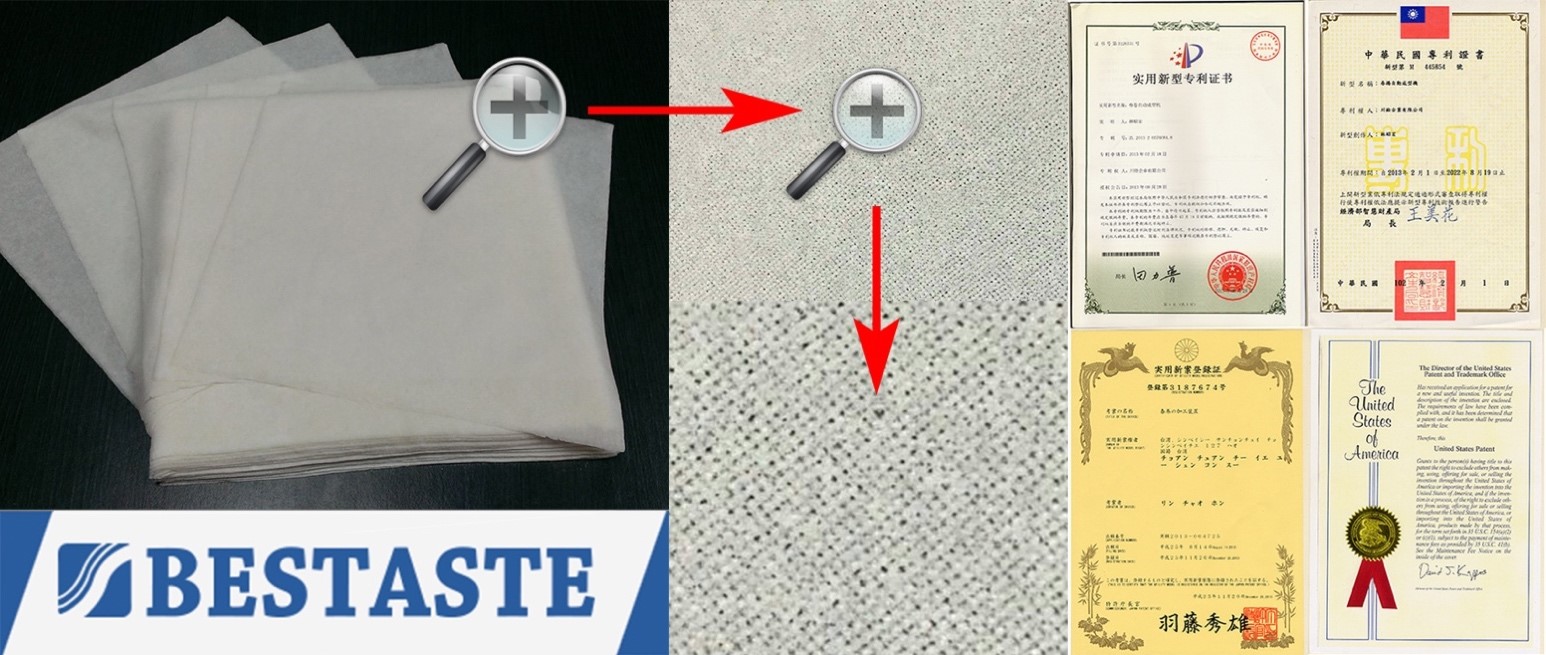

Spring roll pastry making machine ’s Features

Produces more crisp spring roll pastry

Rough surface or Smooth surface of drum can choose.

● Rough

surface of the spring roll pastry has dense pores and more crispy after fired.

● Smooth

surface of the spring roll pastry can produce thinnest thickness pastry 0.2 mm.

● With international

patents.

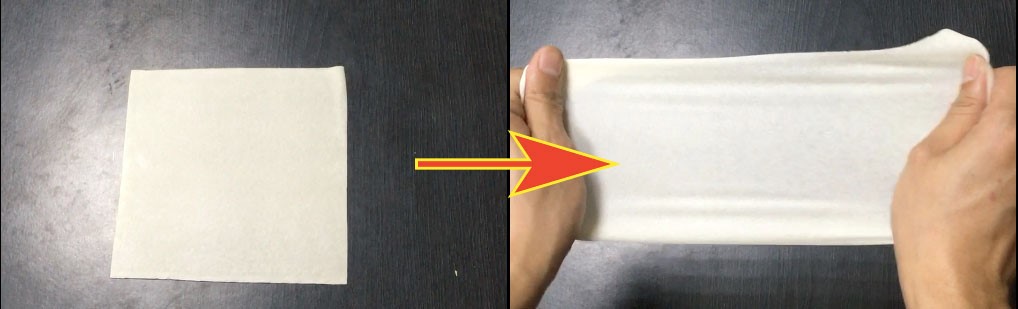

Produce more flexible spring roll pastry

● If

Spring roll pastry doesn’t have flexibility, spring roll pastry will crack when frozen.

Increase spring roll pastry machine use life

● Increase Baking drum life 200%

● Use life can be more than 20 years.

● Increase

the electric heater life 500%

(If not use specially process to make,

about 3 - 6 months the electric heating piece will to be damage.)

BESTASTE's

machines meet

U.S.A FDA standard

● BESTASTE's

machine frame is 100% of the use of 5 mm and 10 mm thick stainless steel plate to produce.

● Other

Manufacturers machine frame uses

the medium-carbon steel (S45C), and then wrapped in a layer of stainless steel sheet on the outside, but which will still rust.

Or use too thin stainless steel plate, it's easy to deformation when used 6 months. (Not

meet the U.S.A FDA standard.)

Have energy-saving effect : Heat

conduct to surface of drum efficiency

● Why saving?

→If heat is not conduct efficiency, heater will continuous supply power, and easily damaged.

● We

use special insulation board, the heat is not lost and have energy-saving effect, the

outer cover will not be broken.

(Not bakelite board, bakelite

board will be broken.)

Egg Roll Making Machine is high-safety and

the failure rate is low

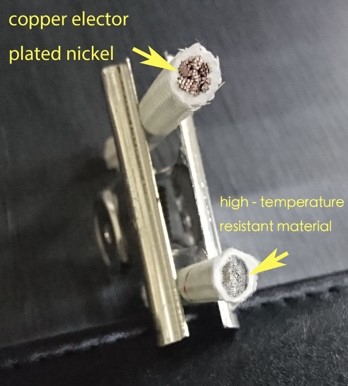

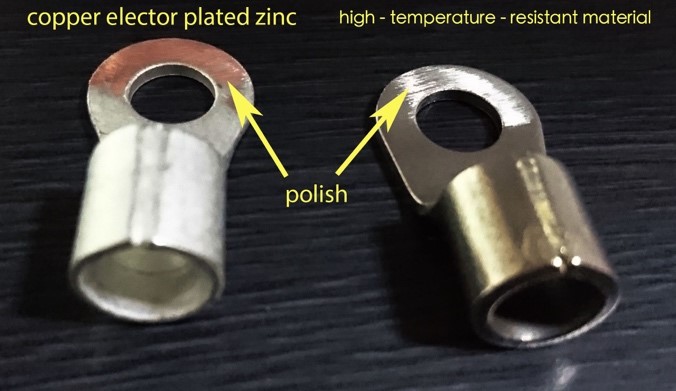

● Inside the baking drum are used high temperature resistant material.

● Use

hydraulic clamp to fixed to ensure safety.

● Many

manufacturers use nickel-plated copper cables to

reduce costs. the connection between the cables and terminals may easily break after long-time use.

High-quality and renowned machine parts : BESTASTE are using international brands to ensure quality

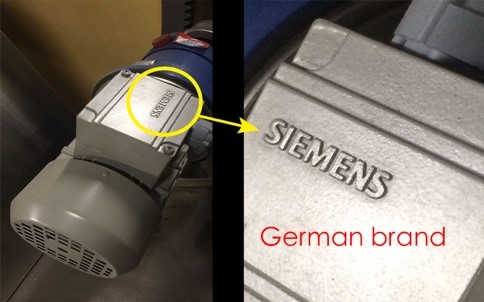

● Motor

use German brand : SIEMENS

● Electronic

components use the Japanese brand :

Fuji Electric (Earth Leakage Circuit Breaker、solenoid valve.)

Omron (Temperature Controller)

Easy to Repair

● Use General Electricity Distribution System : General electricians have a way to deal with, maintenance is simple.

● Electronic parts are easily for purchase.

● Not

to use PLC : General electricians can’t have a way to deal with.

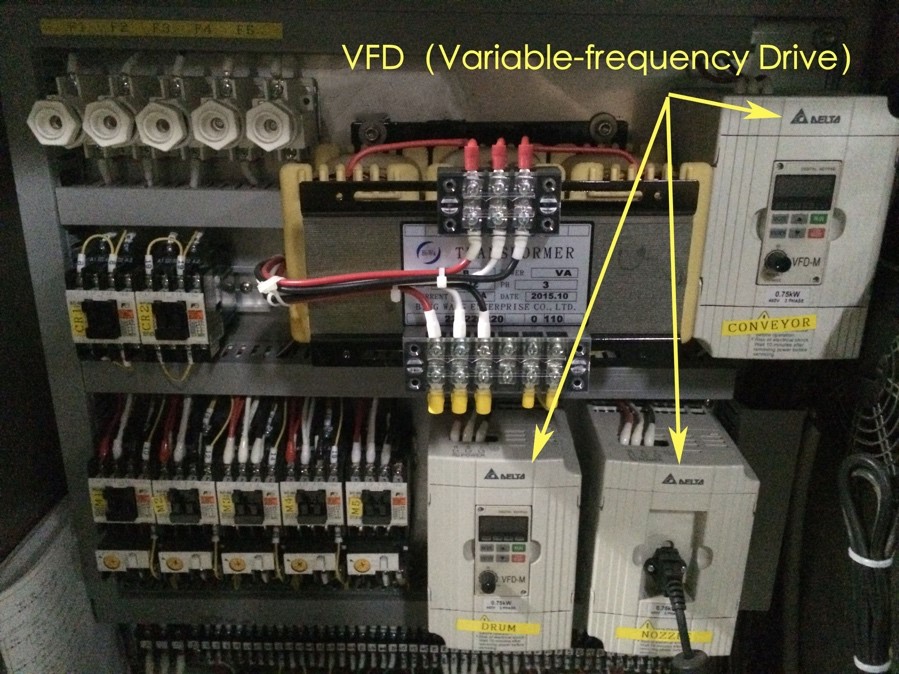

Easy to operate : Any control with numerical display

● The

variable frequency drive (VFD) shown in the figure is used to control the speed of the baking drum, batter (flour) outlet, and cooling conveyor.

Spring roll wrapping making machine ’s Features

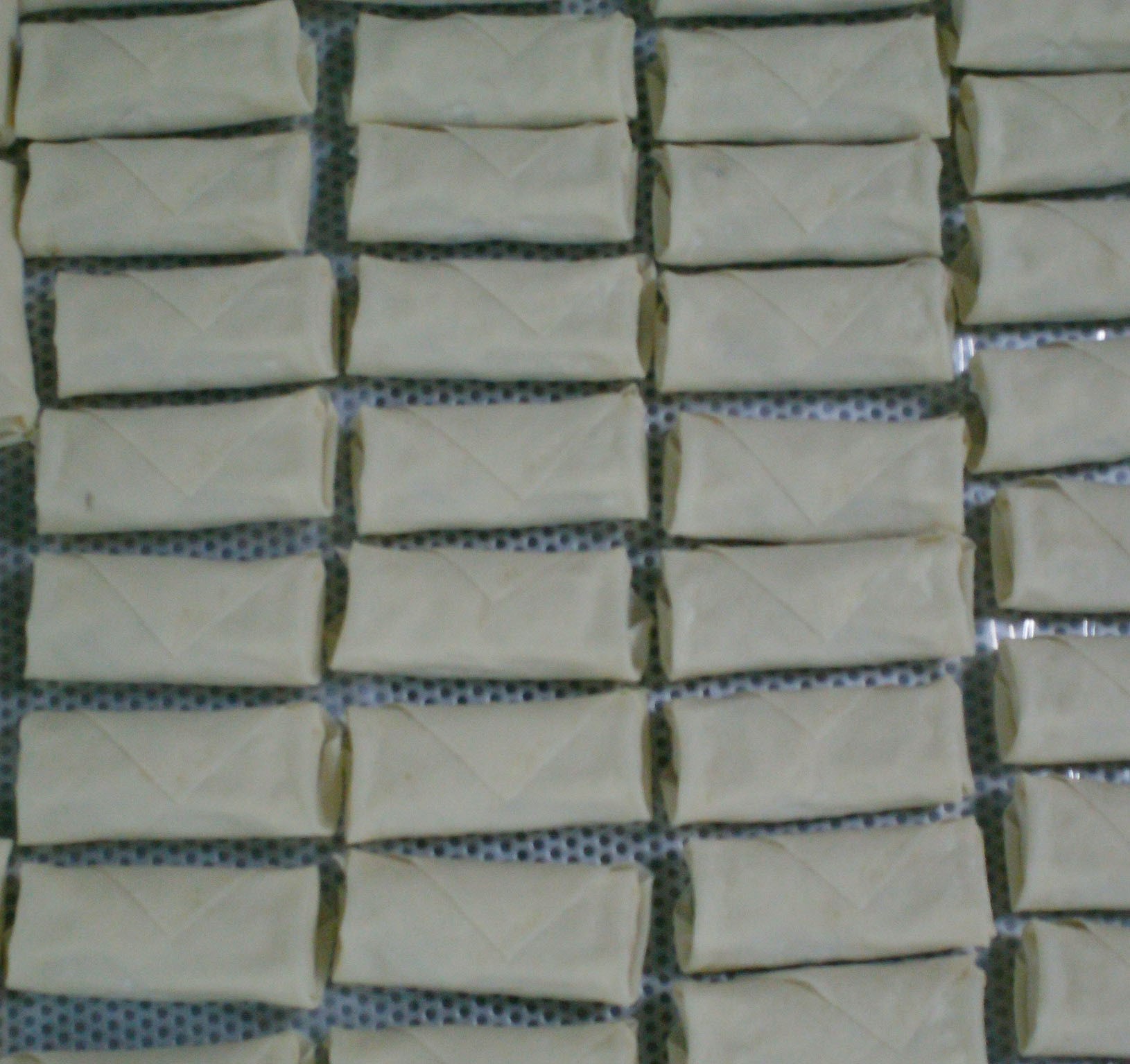

The shape of spring roll

We have round spring roll making machine or flat spring roll making machine two model to offer customer to choose. (Other spring roll wrapping machine, only can do round and tight spring rolls.)

● Round

shape of spring roll : Spring

rolls can be round and tight, the taste is not crisp but more solid feeling. And the appearance is beautiful.

● Flat

shape of spring roll : Flat

spring rolls, the taste is more crisp than the round spring rolls, and the machine out of the crisp feeling, is difficult to produce by hand.

The yield rate of the production line is high up to 999 ‰

● The design of the machine is uses the mechanical movement to achieve the composition of the wrap spring rolls, not use many electronic parts to complete.

● Our spring roll making machine all of the mechanical movements are using the same motor,

● Each action is continuous without mistake; the error rate can be within 1 ‰ in a long time work.

● And other spring roll machine (We called that is type of conveyor belt of spring roll wrapping machine.), is composed of many pneumatic cylinders and sensers,the conveyor belt will be contaminated with oil, will cause the failure rate will be more and more, or can not scroll spring rolls in work to long time.

The filling system is different

● Filling

system and the action of the package spring rolls are mandatory, the location of fillings fixed in the same position in the spring roll pastry will not be biased, if that deviation, the package out of the spring roll shape will be different.

● Use a good filling system, the weight of each spring rolls within ± 5%.

● Spring rolls of the stuffing and the spring roll pastry contains oil, when spring roll wrapping machine start after a long time, the oil will be stick to the machine.

The type of conveyor belt of spring roll wrapping machine, will be mistake when the oil is stick to the conveyor belt. And our machine is using a mandatory action, even if there have oil stick to the machine will not mistake.

So when the customer comes to our company to test the machine, we hope that when the

guests in the comparison machine must be a long time to test.

You must test machine be a long time before you can compare the advantages and disadvantages of the machine.

● BESTASTE’s spring roll making machine, regardless of the spring roll pastry of the soft, hard, thick or thin can be successfully produced.

but the type of conveyor belt of spring roll wrapping machine, the skin must be soft, thick to match the machine can be produce.

spring roll pastry produced thick and soft, spring roll will be crack when frozen for a long time. (because there is no flexibility.)

and the skin is too thick also affect the taste.

Other Advantages

● Can

be washed directly with water.

● Spring

roll making machine and spring roll pastry machine is the same, are 100% stainless steel (SUS 304) production, internal parts are also, do not worry they rust.

● Low failure rate : Water vapor can cause damage to electronic parts. Our spring roll machine uses a motor to complete wrapping spring rolls, will not have this problem.

● The machine area is smaller than the type of conveyor belt of spring roll wrapping machine.

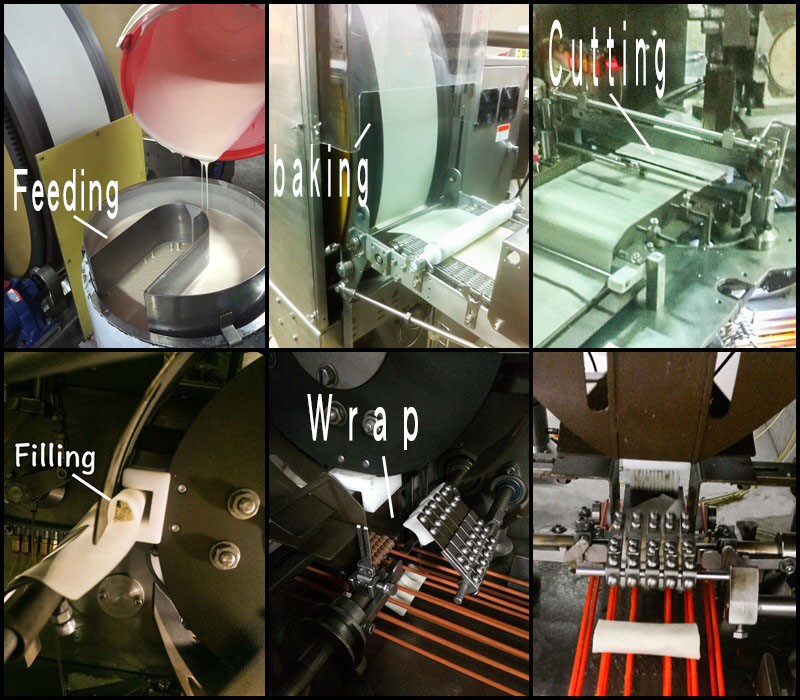

Automatic spring roll making machine production processing

1. Pour

the batter into the spring roll pastry making machine.

2. Wait for the spring roll pastry to produce, and take the spring roll pastry to the automatic spring roll making machine.

3. Automatic spring roll making machine can automatically take the pastry to the machine, and cut the size of customer needs.

4. Then put the filling on the pastry, then the semi-finished spring rolls sent to the machine to wrap spring roll folded and rolled.

5. After

rolled, then put out of the spring rolls.

BESTASTE Features

Most professional

● BESTASTE focus on spring roll pastry making machine and spring roll making machine to research.

● BESTASTE only sell relevant machines in spring roll machine and spring roll wrapper machine.

Most experienced

● BESTASTE has 37 years of experience in using own machines.

● BESTASTE

produce spring roll pastry sold in Taiwan for 37

years. (Other machinery manufacturers do not have

the experience.)

● Customers

repurchase rate 100%.

Most complete equipment

● We have spring roll pastry production line to produce spring roll pastry and wholesale in Taiwan.

● Welcome to visit at any time.

Most high quality

● We

not only care about the quality

of spring roll wrapper machine, but also

care about the spring roll wrapper making machine to produce the high quality of spring roll pastry and the durability

of the machine.

● BESTASTE's

products Meet the CE & FDA & CSA certification.